A speed reducer is a necessary component in most mechanical, hydraulic, electric, and biological motors. The speed reducer slows down the rotations in the engine by increasing the torque on the engine with a series of gears. Without the regulating-boosting power of speed reducers and torque, the speed of the engine would be nearly impossible to stop at high speeds. The main purpose of a speed reducer is to achieve the ideal rotation speed for the ideal function of a particular engine. Since there are so many different kinds of engines, speed reducer manufacturers have created a large variety of speed reducers to use with each engine type.

There are many different types of speed reducers, but the three most common types are the worm reducer, bevel reducer, and spur reducer. Each type of speed reducer has its own benefits and ideal uses.

Spur reducer: A spur reducer is the simplest form of speed reducer. This is a simple gear that has teeth parallel to the axle. This kind of reducer is used in lower-powered engines and smaller engines. It can slip more than other forms of speed reducers.

Bevel reducer: A bevel reducer contains two gears that fit together at an angle between 90 and 180 degrees. This helps control the torque speed of any engine that is high-powered. A bevel reducer slips less than a spur reducer and is often used in vehicles and other large engines.

Worm reducer: A worm reducer is a type of reducer made by speed reducer manufacturers that has a screw with a spiral cut into the screw. The spiral on the screw fits into a second gear. This kind of speed reducer is the most powerful, and is capable of controlling nearly any engine and torque speed. The work reducer will almost never slip, because when the worm stops rotating, the gear can travel neither forward nor backward.

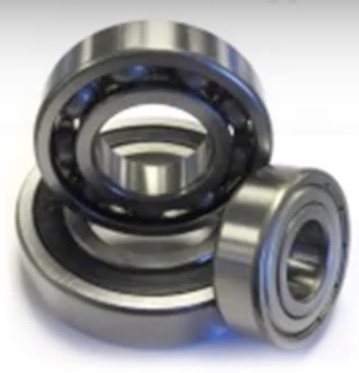

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services