A gear is a mechanical component that transfers mechanical power from one shaft to another. Gear transmission is a common method used to transfer mechanical power. For example, bicycle gears use a chain to transfer force from the pedals to the back wheel. Similarly, a car’s driveshaft uses gears to power the wheels. Gears are necessary to harnes the power of an engine’s revolving crankshaft. Read More…

We offer premium speed reducers and motion control components. These deluxe parts are designed for a wide range of purposes and our engineers are willing to assist you with determining the best speed reducer.

At Nordex, we are dedicated to delivering precision-engineered speed reducers and power transmission solutions that drive efficiency, reliability, and innovation across industries. With decades of expertise, we design and manufacture speed reducers that meet the highest standards of performance, enabling seamless integration into machinery and equipment that demand consistent output and long-term ...

At Winsmith, we take pride in being a trusted leader in the design and manufacturing of high-performance speed reducers that meet the evolving needs of industries worldwide. With decades of experience, we have refined our engineering expertise to deliver precision-driven power transmission solutions that enhance efficiency and reliability in even the most demanding environments.

At Matex Products, we pride ourselves on being a trusted name in motion control solutions, with a strong focus on precision-engineered speed reducers. For decades, we have been dedicated to designing and manufacturing high-quality components that help businesses across industries achieve smoother, more reliable performance in their machinery and automation systems.

More Gear Drive Manufacturers

Gears vary in size, form, and assembly options. When gears transfer power, they affect motion in three ways: speed, force, and direction. These motions can be manipulated by adjusting the size, shape, and tread of intersecting gears.

Advantages & Disadvantages of Gear drives

Gear drives can effectively allow operators to alter velocity ratios. Although they are small in size, they manage to have a high torque capacity. However, when gears are operating at high speeds, they’ll require more lubrication. Gears may be damaged from prolonged use.

Types of Gears

Gears come in different sizes for different applications. For example, gears may be arranged in opposite shafts to transfer power between parallel shafts.

Rack and Pinion Spur

Rack and pinion gears are designed with a small gear (the pinon) on top of the rack, and a straight bar that is notched for the pinion to fit on top. Spur rack and pinions effectively facilitate horizontal motion. The automotive industry often uses helical gears, helical spur gears, or double helical gears. Helical spur gears allow for increased power transmission. Helical gears have inclined teeth.

Spiral bevel gears are also used in automotive applications. Spiral bevel gears tend to have helical teeth and are used to control the wheels through the drive shaft. In a spiral bevel gear, the two spiral gears intersect at a perpendicular angle. Spiral bevel gears tend to be very powerful. Zero bevel gears operate similarly, however, the teeth have a gentle curve instead of a sharp spiral.

A herringbone gear respembles two helical gears side by side, combined into one gear. In herringbone gears, there is no space between the inclined teeth. Cross helical gears are used on shafts that are neither parallel or intersect.

Cross helical gears are used on shafts that are neither parallel or intersect. Worm gears are also known as worm and wheel. ‘Worm’ refers to a long rod with a spiral. The worm has the power to rotate the gear, but the gear cannot rotate the worm. In hypoid gear systems, the center lines of the two shafts do not cross. Alternately, the shafts in a hypoid gear arrangement have irregularities in their center lines.

Choosing the Right Gear Drive Suppliers

To make sure you have the most positive outcome when purchasing gear drives from a gear drive supplier, it is important to compare at least 4 companies using our list of gear drive suppliers. Each gear drive supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each gear drive business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple gear drive companies with the same message.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

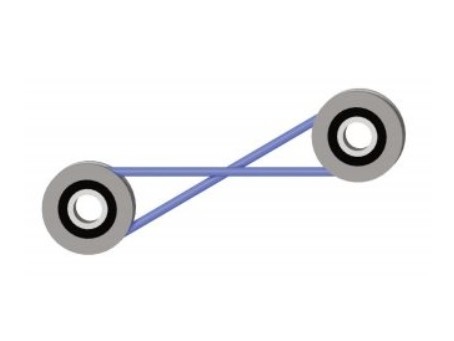

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

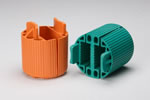

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services