An instrument having aligned input and output shafts is a planetary gearbox. The most efficient and compact way to transfer the most torque is using a planetary gearbox. They are frequently used in the automobile industry as a crucial part of automatic transmission applications. A planetary gearbox type uses a center of rotation for its input and output. As a result, the output and input shafts are aligned, and the input gear’s center spins around the output section’s center. The compact alternative to typical pinion-and-gear reducers is always planetary gearing, which has an inherent cylindrical assembly and inline shafting. Read More…

We offer premium speed reducers and motion control components. These deluxe parts are designed for a wide range of purposes and our engineers are willing to assist you with determining the best speed reducer.

At Nordex, we are dedicated to delivering precision-engineered speed reducers and power transmission solutions that drive efficiency, reliability, and innovation across industries. With decades of expertise, we design and manufacture speed reducers that meet the highest standards of performance, enabling seamless integration into machinery and equipment that demand consistent output and long-term ...

At Winsmith, we take pride in being a trusted leader in the design and manufacturing of high-performance speed reducers that meet the evolving needs of industries worldwide. With decades of experience, we have refined our engineering expertise to deliver precision-driven power transmission solutions that enhance efficiency and reliability in even the most demanding environments.

At Matex Products, we pride ourselves on being a trusted name in motion control solutions, with a strong focus on precision-engineered speed reducers. For decades, we have been dedicated to designing and manufacturing high-quality components that help businesses across industries achieve smoother, more reliable performance in their machinery and automation systems.

More Planetary Gearbox Manufacturers

How Planetary Gearboxes Work

A planetary gearbox, also known as a planetary gear reducer or planetary gear drive, is a highly efficient power transmission solution used across a wide array of industrial and automation applications. Renowned for their compact design, high torque density, and long service life, planetary gearboxes are engineered to meet the rigorous demands of modern servo systems, robotics, conveyors, and heavy machinery. This gearbox type stands apart by offering remarkable reliability, low maintenance requirements, and an exceptional balance of power and precision, making it a top choice for engineers and equipment manufacturers worldwide.

The term "planetary gearbox" derives from the gear system’s resemblance to the solar system. In this arrangement, a central "sun" gear is surrounded by several "planet" gears, all encased within an outer "ring" gear with internal teeth. The sun gear, which is typically the input, transmits motion and torque to the orbiting planet gears. These planet gears, mounted on a rotating carrier, revolve around the sun gear while meshing with both the sun and the ring gear. The carrier itself is connected to the output shaft, which delivers the multiplied torque and reduced speed to the driven application.

The basic planetary gear system consists of four main components:

- Sun Gear: The central gear, typically serving as the input.

- Planet Gears: Multiple gears that orbit the sun gear, distributing load and torque.

- Ring Gear: The fixed outer gear with internal teeth.

- Planet Carrier: The framework that holds and rotates the planet gears, forming the output.

During operation, input power rotates the sun gear, causing the planet gears to spin and move along the interior of the ring gear. The planet carrier, attached to the output shaft, rotates as the planet gears revolve, thus transmitting torque to the application. This multi-point contact design not only enhances torque capacity but also ensures exceptional load distribution, minimal backlash, and reliable operation even under demanding conditions.

Advantages and Key Features of Planetary Gearboxes

Are you exploring the benefits of planetary gearboxes for your next project? Here’s why this gear system is favored in precision applications:

- High Torque Density: The load is distributed across multiple planet gears, enabling planetary reducers to transmit more torque relative to their size compared to other gearbox types.

- Compact Footprint: Their inline configuration allows for a smaller, lighter gearbox that fits into tight spaces—ideal for servo motors and automation equipment.

- Low Backlash: Precision manufacturing and the multi-gear engagement minimize backlash, making them suitable for robotics, CNC machinery, and positioning systems.

- High Efficiency: Planetary gear trains offer high mechanical efficiency (typically 95% or better), reducing energy loss and heat generation.

- Quiet Operation: The distribution of force and precise meshing result in quieter performance, an asset in noise-sensitive environments.

- Robustness and Durability: The even load sharing extends system lifespan, reduces wear, and minimizes maintenance intervals.

- Versatile Ratios: Planetary gearboxes can achieve a wide range of reduction ratios, accommodating both high-speed and high-torque applications.

Interested in discovering which planetary gear reducer is right for your requirements? Jump to our section on selecting a planetary gearbox manufacturer or keep reading for in-depth comparisons.

Drawbacks of Planetary Gearboxes

While planetary gearboxes excel in many areas, it’s essential to weigh their limitations before making a purchasing decision. Here are key considerations for engineers and buyers evaluating planetary gearbox solutions:

- Higher Cost: The intricate design, precision manufacturing, and greater number of components typically make planetary gearboxes more expensive than simple spur or helical gearboxes.

- Complex Assembly: Proper alignment and assembly are critical. If the planet gears are not equidistant or are positioned too closely to the sun gear, the gearbox can become imbalanced, leading to increased wear, vibration, and potential failure.

- Heat Dissipation: Due to their compact design and high power density, planetary gearboxes can generate significant heat—especially in continuous-duty or high-speed applications. In such cases, additional cooling solutions (such as forced-air or liquid cooling) may be necessary to maintain performance and prevent premature failure.

- Axial Load Considerations: The choice of gear type impacts axial and radial load handling. Spur gear-based planetary reducers generate minimal axial forces, whereas helical gear planetary drives—with helix angles between 10 and 30 degrees—produce higher axial forces. Bearings in helical planetary gearboxes must be rated for these additional loads.

- Limited Gear Ratios: While planetary gearboxes offer a range of reduction ratios, extremely high ratios may require multiple stages, increasing size and complexity.

Applications of Planetary Gearboxes

Where are planetary gearboxes used? These gear drives are a cornerstone of precision motion control and heavy-duty power transmission across dozens of industries. Their ability to deliver high torque output in a compact, efficient package makes them ideal for both industrial and mobile machinery.

Industrial and Manufacturing Applications

- Conveyor Systems: Planetary gearboxes provide reliable speed reduction and torque multiplication for material handling conveyors, assembly lines, and baggage systems.

- Mixers, Agitators & Drives: Their low backlash and high efficiency enhance mixing consistency and process reliability in food processing, chemical, and pharmaceutical manufacturing.

- Hoisting Equipment: Used in cranes, hoists, and winches for precise, powerful lifting with minimal maintenance.

- Sugar and Boiler Mills: Heavy-duty planetary drives withstand high loads in mill extraction and industrial processing.

- Automated Machinery: Robotics, pick-and-place machines, and CNC equipment depend on planetary reducers for accurate position control and rapid cycle times.

- Pumps and Compressors: Efficient power transmission extends pump life and reduces energy consumption.

- Injection Mechanisms: Planetary gearboxes power precision injectors in coil tubing and plastic molding operations.

Mobile and Off-Highway Equipment

- Tractors & Agricultural Machinery: Planetary gear systems deliver the high torque needed for plows, combines, and harvesters while minimizing space requirements.

- Construction Equipment: Wheel drives, track drives, and slew drives utilize planetary gearboxes for rugged, dependable torque transmission in excavators, loaders, and bulldozers.

- Automotive Transmissions: Automatic gearboxes in passenger vehicles and commercial trucks frequently employ planetary gearing for smooth shifting and compact packaging.

- Turbine Engines: Planetary gear trains balance high input speeds and torque for efficient energy conversion in wind turbines and aerospace applications.

- Electric Screwdrivers & Power Tools: Compact planetary gearboxes enable cordless tools to deliver strong, consistent torque in a lightweight package.

Wondering which planetary gearbox is best for your unique application? Contact leading gearbox manufacturers for custom quotes, technical support, and expert recommendations.

Planetary Gearbox Types, Configurations, and Customization Options

Planetary gearboxes are available in a wide variety of configurations to suit specific industry needs. Understanding these options helps buyers select the optimal gearbox for performance, longevity, and cost-effectiveness.

Common Planetary Gearbox Types

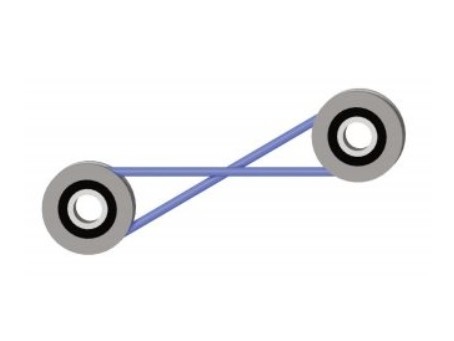

- Inline Planetary Gearboxes: The most popular design, aligning the input and output shafts for straightforward integration with servo motors and actuators.

- Right-Angle Planetary Gearboxes: Utilize bevel or hypoid gears to change the direction of power transmission, ideal for applications requiring space-saving or specific mounting orientations.

- Coaxial and Multi-Stage Gearboxes: Multiple planetary stages can be stacked to achieve very high reduction ratios while maintaining efficiency and compactness.

- Spur vs. Helical Planetary Gearboxes: Spur planetary reduces are more cost-effective and efficient, while helical types offer quieter operation, higher torque, and smoother motion but may require improved bearing support for axial loads.

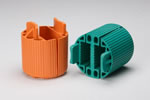

Customization and Engineering Options

- Bearing Types: Selection between ball, roller, or needle bearings affects load capacity and operating life.

- Lubrication Systems: Options include grease, oil bath, or automatic lubrication for extreme-duty cycles.

- Materials & Sealing: High-strength steel, aluminum, and specialty coatings offer enhanced corrosion resistance and temperature tolerance.

- Mounting and Connection: Flange, foot, and shaft mounting options allow flexible integration into OEM equipment or retrofit upgrades.

- Input/Output Adaptation: Custom couplings, adapters, and gear ratios ensure seamless connection with servo motors, AC/DC drives, or hydraulic motors.

Not sure which configuration fits your needs? Ask a planetary gearbox expert for a free consultation and tailored product recommendations.

Choosing the Right Planetary Gearbox Manufacturer

Selecting the best planetary gearbox manufacturer is a critical step for OEMs, system integrators, and buyers seeking reliable performance and long-term value. Here’s a step-by-step guide to help you evaluate suppliers and make an informed buying decision:

- Define Performance Requirements: Identify torque, speed, duty cycle, and environmental factors for your application. Consider factors like backlash tolerance, efficiency, and expected service life.

- Evaluate Engineering Support: Choose manufacturers that offer robust technical assistance, CAD models, customization, and rapid prototyping to streamline your design process.

- Assess Quality Certifications: Look for ISO 9001, CE, and other certifications ensuring consistent quality and safety standards.

- Compare Product Range: Review each supplier’s catalog for options like inline vs. right-angle, single- vs. multi-stage, and spur vs. helical planetary gearboxes.

- Check After-Sales Service: Consider warranty terms, spare parts availability, and on-site support for maintenance and repairs.

- Request Custom Quotes: Use our list of planetary gearbox manufacturers to contact at least four suppliers. Each profile features areas of expertise, capabilities, and a direct inquiry form for technical questions or quote requests.

- Review Online Resources: Visit each manufacturer’s website using our proprietary preview tool to explore product documentation, case studies, and customer testimonials.

- Submit a Unified RFQ: Save time by using our streamlined RFQ form to send your requirements to multiple gearbox manufacturers at once—ensuring you receive competitive offers and tailored solutions.

Frequently Asked Questions About Planetary Gearboxes

What is the difference between a planetary gearbox and a standard gearbox?

A standard gearbox, such as a spur or helical gear reducer, typically uses parallel shafts and transmits power through one or two gears. In contrast, a planetary gearbox features a central sun gear, multiple planet gears, and a ring gear—resulting in higher torque density, compact size, and lower backlash. Planetary gearboxes are ideal for applications demanding precision, efficiency, and long service life.

How do I select the correct planetary gearbox ratio?

Choosing the optimal gear reduction ratio depends on your application’s speed and torque requirements, motor characteristics, and duty cycle. Higher ratios mean lower output speed and higher torque. Consult with gearbox manufacturers or use online sizing calculators to determine the best ratio for your specific needs.

Can planetary gearboxes handle continuous operation?

Yes, high-quality planetary gearboxes are designed for continuous-duty cycles, but appropriate lubrication, cooling, and material selection are vital for reliable operation. For high-speed or high-load applications, verify that your gearbox is rated for continuous use and consider additional cooling if necessary.

Where can I find 3D models or CAD files for planetary gearboxes?

Most reputable planetary gearbox manufacturers offer downloadable CAD models, datasheets, and technical documentation on their product pages. If you require custom files or engineering support, contact the manufacturer directly via their inquiry form.

How do planetary gearboxes improve energy efficiency?

Planetary gearboxes achieve high mechanical efficiency (often above 95%) by distributing load evenly, minimizing friction, and reducing energy losses. This makes them an excellent choice for applications aiming to lower operational costs and improve overall system performance.

Ready to Get Started?

If you’re searching for the best planetary gearbox for your business, industrial automation project, or OEM equipment, leverage our comprehensive supplier directory to connect with leading manufacturers. Compare technical specifications, request engineering support, and receive custom quotes—empowering you to make an informed, cost-effective gearbox selection that delivers long-term value and reliable performance.

Still have questions? Contact our expert team for personalized recommendations or explore our knowledge base for more in-depth guides, application notes, and industry insights on planetary gearboxes and power transmission solutions.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services