A gear is a device that transfers power from one shaft to another. A set of gears and their case, most frequently seen in automobiles, are simply referred to as “gear boxes.” Transmissions enable machinery to run effectively and even help slow down and shut down machinery because most motor vehicle engines have high operating and idling speeds. Gearboxes move energy from one spinning power source to another in cars, turbines, and other large machines. Read More…

We offer premium speed reducers and motion control components. These deluxe parts are designed for a wide range of purposes and our engineers are willing to assist you with determining the best speed reducer.

At Nordex, we are dedicated to delivering precision-engineered speed reducers and power transmission solutions that drive efficiency, reliability, and innovation across industries. With decades of expertise, we design and manufacture speed reducers that meet the highest standards of performance, enabling seamless integration into machinery and equipment that demand consistent output and long-term ...

At Winsmith, we take pride in being a trusted leader in the design and manufacturing of high-performance speed reducers that meet the evolving needs of industries worldwide. With decades of experience, we have refined our engineering expertise to deliver precision-driven power transmission solutions that enhance efficiency and reliability in even the most demanding environments.

At Matex Products, we pride ourselves on being a trusted name in motion control solutions, with a strong focus on precision-engineered speed reducers. For decades, we have been dedicated to designing and manufacturing high-quality components that help businesses across industries achieve smoother, more reliable performance in their machinery and automation systems.

More Gearbox Manufacturers

Types of Gearboxes: Comprehensive Guide for Industrial and Automotive Applications

Gearboxes—also known as gear reducers, transmission boxes, or speed reducers—play a pivotal role in a wide range of mechanical and industrial power transmission systems. Whether you are engineering heavy-duty machinery, optimizing automotive drivetrains, or looking to improve efficiency in manufacturing, understanding the different types of gearboxes is essential for selecting the right solution for your requirements. This guide covers the major gearbox classifications, their specific design characteristics, operational advantages, and key considerations for buyers and engineers alike.

How Are Gearboxes Classified?

Gearboxes are generally classified based on their application (industrial or automotive), gear arrangement (such as helical, bevel, or planetary), and mode of operation (manual or automatic). Each configuration offers unique benefits for specific torque, speed, and efficiency needs. Let’s explore the major types and their most common use cases.

Industrial Gearboxes

Industrial gearboxes are engineered to withstand rigorous operational demands and are widely used in sectors such as manufacturing, mining, chemical processing, power generation, and materials handling. Their robust designs enable precision torque control, high load capacity, and long service life even in harsh environments.

Worm Reduction Gearboxes

Worm reduction gearboxes, also known as worm gear reducers, are essential for heavy-duty power transmission applications. They are commonly specified where significant speed reduction is required between non-intersecting shafts—such as conveyor systems, mixers, and material handling equipment. The core of a worm gearbox consists of a large-diameter worm wheel and a worm (screw), with the teeth of the wheel meshing precisely with the worm for smooth, quiet operation.

Advantages of worm gearboxes include compactness, self-locking capability (preventing back-driving), and high shock-load resistance. These features make worm reducers ideal for industries like mineral processing, cement, chemicals, steel manufacturing, and fertilizer production. Their ability to handle high reduction ratios in a single stage is a key benefit for engineers designing space-constrained or safety-critical machinery.

Planetary Gearboxes

Planetary gearboxes—also referred to as epicyclic gearboxes—feature a unique arrangement where three or more planet gears orbit a central sun gear, all enclosed within a ring gear. This configuration ensures optimal load distribution, high torque density, and remarkable efficiency in a compact design. Planetary gear systems are renowned for their durability, precision, and versatility, making them the preferred choice for robotics, automation, servo drives, wind turbines, and mobile machinery.

Key benefits of planetary gearboxes include:

- High torque-to-weight ratio

- Exceptional positional accuracy (low backlash)

- Compact dimensions suitable for space-limited installations

- Modular mounting options—including flange, shaft, or foot designs, as well as solid or hollow output formats

- Extended service life under continuous or dynamic loading conditions

For detailed technical specifications and sourcing options, see our planetary gearbox supplier directory.

Typical Applications of Planetary Gearboxes

- Industrial automation (robotics, pick-and-place machines)

- Printing and packaging equipment

- Renewable energy systems (wind turbine pitch drives)

- Medical equipment (MRI tables, surgical robots)

- Mobile construction machinery

- Precision machine tools

Coaxial Helical Inline Gearboxes

Coaxial helical inline gearboxes are designed for heavy-duty industrial applications where maximum efficiency and reliability are paramount. Their helical gear teeth enable smooth transmission of high torque loads, minimize noise, and reduce vibration, ensuring long-term operational stability. Manufactured to exacting standards, these gearboxes are ideal for bulk material conveyors, crushers, agitators, and other demanding applications.

Are you looking for energy-efficient gearbox solutions to maximize output and minimize downtime in your facility? Consider coaxial helical inline gearboxes for their proven performance and flexibility in a wide range of industrial environments.

Bevel Gearboxes

Bevel gearboxes utilize bevel gears—conical gears with intersecting shafts—allowing the transfer of rotary motion between perpendicular (or non-parallel) shafts. A distinctive feature is the curved or straight teeth situated on the cone-shaped surface, which enables smooth, high-precision power transmission even at high speeds. Bevel and bevel-helical gearboxes are commonly found in mining equipment, conveyor drives, marine propulsion, and right-angle power transmission systems.

Skew Bevel Helical Gearboxes

Skew bevel helical gearboxes feature a robust, monolithic housing and precisely machined gears, making them ideal for heavy-load, high-shock applications. These gear reducers are valued for their mechanical efficiency, high load capacity, and ability to accommodate custom gear ratios and configurations. Once integrated with a suitable motor, skew bevel helical gearboxes provide significant mechanical advantage, making them indispensable in bulk handling, cranes, and heavy processing equipment.

Wondering which gear arrangement is best for your application? Contact our engineering support team for gearbox selection assistance and custom design services.

Automobile Gearboxes: Transmission Types & Innovations

Automobile gearboxes, also known as vehicle transmissions, are classified into manual and automatic transmission systems. Each transmission type caters to specific performance, comfort, and fuel efficiency requirements. Understanding the distinctions between these automotive gearbox designs is crucial for vehicle manufacturers, fleet operators, and performance enthusiasts alike.

Manual Transmission Gearboxes

Manual transmissions, or “stick shifts,” require the driver to manually engage and disengage gears using a clutch pedal and gear lever. They are valued for their direct control, driving engagement, and typically higher mechanical efficiency compared to automatics.

Constant Mesh Gearboxes

Constant-mesh gearboxes—also referred to as synchronized transmissions—maintain continuous engagement between the drive gear, cluster gear, and main shaft gears. Gears rotate freely on the main shaft until locked in place by a dog clutch, which is actuated via the shift linkage. Synchronizers are built-in to prevent gear clash and ensure smoother, quieter shifting action. This transmission design is common in modern manual vehicles, motorcycles, and some commercial trucks due to its reliability and ease of use.

Are you interested in learning how synchronized transmissions improve vehicle performance and driver comfort? Explore advanced gearbox technologies here.

Pre-Selector Gearboxes

Pre-selector gearboxes were an innovative predecessor to contemporary automatics, featuring a selector lever (often mounted on the steering column) that allowed the driver to “pre-select” the next gear. A planetary gear system completed the shift when a foot pedal was depressed. While largely obsolete in modern vehicles, pre-selector gearboxes were notable for their rapid gear changes and use in luxury cars and early race cars.

Automatic Transmission Gearboxes

Automatic transmissions automatically change gear ratios as the vehicle moves, freeing the driver from manually shifting gears. These systems enhance convenience, especially in stop-and-go traffic, and can be optimized for smoothness, acceleration, or fuel efficiency. There are several main types of automatic gearboxes:

Automated-Manual Transmission Gearboxes (AMT)

Automated-manual transmissions (AMTs) blend the mechanical layout of a conventional manual gearbox with electronic sensors, actuators, and control units. The result is an automatic shifting experience with improved fuel efficiency. However, AMTs are sometimes characterized by less smooth gear changes at low speeds. They are commonly found in compact cars and commercial vehicles where cost and efficiency are primary considerations.

- Cost-effective alternative to traditional automatics

- Lower maintenance compared to CVTs or dual-clutch systems

- Good fuel economy, especially for highway driving

Torque Converter Gearboxes

The torque converter is the most prevalent type of automatic transmission. It uses a fluid coupling to transmit engine power to the drivetrain, allowing smooth acceleration from a standstill and eliminating the risk of stalling. While torque converter automatics may have slightly lower mechanical efficiency compared to manual gearboxes, advanced designs now incorporate lock-up clutches and multi-stage gears to improve fuel economy and response. These gearboxes are widely used in passenger cars, SUVs, and light trucks.

- Seamless power delivery and acceleration

- Enhanced comfort in urban and stop-and-go driving

- Advanced control features for improved efficiency

- Durable and low-maintenance

Continuously Variable Transmission (CVT) Gearboxes

Continuously variable transmissions (CVTs) offer a stepless range of gear ratios, allowing the engine to operate at optimal RPM for maximum efficiency. Common in hybrid vehicles and modern compact cars, CVTs use a system of pulleys and belts or chains. Benefits include:

- Superior fuel efficiency, especially in city driving

- Smooth, uninterrupted acceleration

- Reduced mechanical complexity

To compare CVT vs. torque converter vs. dual-clutch transmission, see our automotive gearbox comparison guide.

Dual-Clutch Transmission (DCT) Gearboxes

Dual-clutch transmissions combine the efficiency of a manual with the convenience of an automatic. Two separate clutches engage alternate gear sets, enabling rapid, seamless shifts and enhanced driving dynamics. DCTs are increasingly popular in performance vehicles and premium models.

- Ultra-fast gear changes for sporty driving

- Improved fuel economy over traditional automatics

- Widely adopted in motorsports and high-performance road cars

How to Select the Right Gearbox for Your Application

Selecting the ideal gearbox for your project requires careful consideration of several technical and commercial factors. Here’s a step-by-step approach to help you evaluate gearbox options:

- Define Application Requirements: What torque, speed, and duty cycle does your equipment require? Is noise reduction or efficiency the top priority?

- Assess Environmental Conditions: Will the gearbox operate in harsh, dusty, or corrosive environments? Consider sealing, lubrication, and material options.

- Determine Mounting and Footprint Needs: Do you need a flange, shaft, or foot-mounted solution? What space constraints exist?

- Evaluate Maintenance and Serviceability: Is ease of maintenance important for your operation? Look for modular designs and accessible service points.

- Analyze Cost, Lead Time, and Warranty: Balance initial investment with lifecycle costs, delivery schedules, and after-sales support.

Still unsure which gearbox is best? Ask our experts for a custom recommendation tailored to your industry and application.

Popular Gearbox Use Cases and Industry Applications

- Manufacturing: Conveyor drives, presses, extruders, and assembly lines

- Mining & Minerals: Crushers, draglines, bulk material handling

- Automotive: Drivetrains, differentials, electric vehicle gearboxes

- Renewable Energy: Wind turbine pitch and yaw drives

- Food & Beverage: Mixers, bottling lines, packaging equipment

- Marine: Propulsion, winches, anchor handling

- Aerospace & Defense: Actuators, landing gear mechanisms

- Construction: Cranes, hoists, concrete mixers

- Robotics & Automation: Precision motion control, AGVs, industrial robots

Benefits of Upgrading to Modern Gearbox Technology

Upgrading to a modern, high-efficiency gearbox can deliver significant operational and financial benefits, including:

- Reduced energy consumption and lower operating costs

- Increased equipment lifespan and reliability

- Minimized downtime through advanced diagnostics and condition monitoring

- Enhanced precision and process control in automated systems

- Improved safety features, such as overload protection and self-locking mechanisms

- More compact and lightweight designs

Ready to modernize your facility’s power transmission systems? Request a gearbox upgrade consultation or compare leading gearbox manufacturers below.

Choosing the Proper Gearbox Manufacturer: What to Look For

To ensure maximum value and reliability when sourcing industrial gearboxes or automotive transmissions, it is essential to compare multiple gearbox manufacturers. Here’s how to make an informed decision:

- Review each gearbox manufacturer’s business profile for expertise, certifications, and product range

- Assess technical capabilities and custom engineering services

- Request quotes using standardized RFQ forms for easy comparison

- Use our proprietary website previewer to evaluate each company’s specialization and reputation

- Check for warranty terms, after-sales support, and global service networks

- Consider lead times, inventory availability, and shipping options for urgent projects

Looking for the best gearbox supplier for your application? Compare top gearbox companies now and request multiple quotes in minutes.

Each gearbox manufacturer listing includes a direct contact form—streamlining your procurement process and helping you secure the best pricing and delivery for your next project.

Frequently Asked Questions About Gearboxes

- What is the difference between a gearbox and a speed reducer? A speed reducer is a type of gearbox designed specifically to reduce input speed, while a gearbox can also change direction or multiply torque.

- How do I calculate the required gear ratio for my application? Use the formula: Gear Ratio = Output Speed / Input Speed. Consider torque, load, and duty cycle for proper selection.

- What is the lifespan of a typical industrial gearbox? With proper maintenance, quality gearboxes can last 10–20 years or more, depending on operating conditions and load factors.

- Can I retrofit my existing machinery with a new gearbox? Yes, many modern gearboxes are available in standard mounting footprints or with custom adapters for retrofit projects.

- What maintenance is required for gearboxes? Regular lubrication, seal inspection, and condition monitoring are recommended to maximize service life and prevent failures.

- Are there noise-reducing gearboxes for quiet environments? Helical and planetary gearboxes are typically quieter due to the design of their gear teeth and internal arrangements.

Get Started: Request Quotes and Compare Gearbox Options

Take the next step in your project by exploring our curated list of gearbox manufacturers. Each profile provides in-depth information about their product lines, engineering capabilities, and industry expertise. Use our simple request-for-quote (RFQ) tool to contact multiple companies and receive competitive offers tailored to your requirements.

Have specific questions or need help with gearbox selection, integration, or retrofit projects? Contact our technical team for expert support and recommendations.

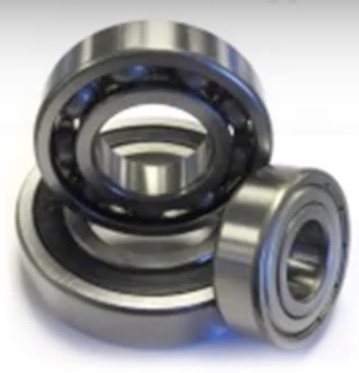

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services