Even something as basic as the wipers on the windshield of a car has a very small gear motor that turns the gears of the wiper arms and allows them to move back and forth. Of course, gear motors can also be much larger than this and they can have enough power to move a large industrial conveyor belt or lift a pulley with a heavy load. Read More…

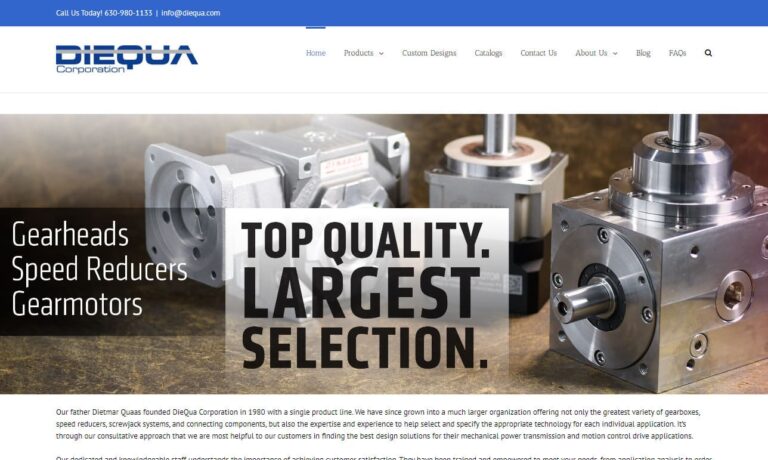

We offer premium speed reducers and motion control components. These deluxe parts are designed for a wide range of purposes and our engineers are willing to assist you with determining the best speed reducer.

Cleveland Gear Co. has specialized in speed control technology including a variety of quality manufactured speed reducers since 1912. We have successfully developed speed reducers for material handling, mineral processing, and more. You will find that our products have uncompromising quality, making all others less than the best. We will fulfill your exact requirements and that's what continues...

At JHFOSTER, we pride ourselves on our commitment to excellence in engineering and innovation. Our company specializes in designing and manufacturing high-performance speed reducers that cater to a wide range of industries. Our products are crafted with precision and reliability in mind, ensuring they meet the rigorous demands of modern industrial applications.

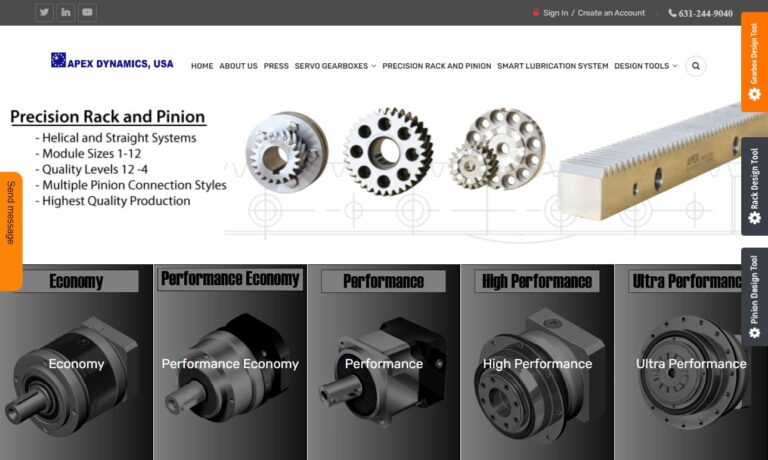

Apex Dynamics, Inc. is a worldwide leader in manufacturing of planetary gearboxes. Based on more than twenty years of accumulated manufacturing and marketing experience, plus the highest level of technical production capabilities, Apex Dynamics, Inc. designed and built a technically advanced, high speed, low backlash servo application planetary gearbox.

We manufacture highly advanced cyclo reducers which utilize new modifications which allow for 2-speed capabilities. This new technology efficiently provides a high amount of torque at a low speed. Our engineers put a focus on developing the most innovated and cost efficient solutions. We take pride in saying that we are an industry leader that is a global supplier. Feel free to give one of our...

More Gear Motor Manufacturers

The motor is encased in a unit that protects it from moisture or impact on the outside. With heavier motors in industrial applications, this casing is usually made from metal for added protection and durability. Inside the casing, the motor engages with a series of reduction gears when it is activated, and the torque from these turns the drive shaft that extends out of the gear motor unit. Typically, a gear is also mounted on this exterior part of the drive shaft in order to exert force on whatever piece of equipment it is being used with.

Another application of this can be found in a household or industrial garage door opener. A gear motor is installed inside the unit's box, and this gear motor engages with a gear on a central drive shaft that turns a sprocket connected to the chain that pulls and lowers the garage door. Without a strong gear motor, it wouldn't be possible for the door to be opened or closed at the push of a button.

Gear motors that are purchased on their own for exterior installation usually have a mounting platform built on them so that they can be bolted directly to a surface. This secure setup ensures that all of the torque generated by the motor is used efficiently.

A gear motor manufacturer can consult with you about the best solution for the needs of your application. Having a motor that exerts enough power to accomplish your equipment process is critical if you want a reliable unit the doesn't put too much strain on the motor.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services